Technical Details Of Cone Mining Mills

.jpg)

7 Key Technical Parameters of Cone Crusher You Need to Know

2025年3月6日 This article provides a detailed overview of the key technical parameters of cone crusher, covering their design, performance, and operation It will also address how these parameters affect crushing efficiency, output quality, and machine longevity, and provide Cone crushers are essential machines in the mining industry, known for their compressionbased crushing methods They work by compressing The Best Cone Crushers for Hard Rock MiningSBM Industrial Tec2025年3月20日 Cone crusher is one of the most widely used types of crushing equipment in various industries, particularly in mining, construction, and aggregates Known for their What is a Cone Crusher?SBM Industrial Technology Group2025年2月28日 Cone crushers are essential machines in the mining industry, known for their compressionbased crushing methods They work by compressing materials between two The Best Cone Crushers for Hard Rock MiningSBM Industrial The R2500 is our largest cone crusher It is designed to handle precrushing duties from the primary crusher and to prepare feed for a SAG mill to reduce retention times in the mill A Raptor® Cone Crushers for Mining and AggregateCone Mill Also Known As A Conical Mill Or Cone Milling Machine, is a versatile pharmaceutical and chemical processing equipment used for size reduction and granulation of powders and granules It features a conicalshaped milling Cone Mill Design, Mfg Supply by

.jpg)

Technical specifications of cone crusher of 350 to 400 tph capacity

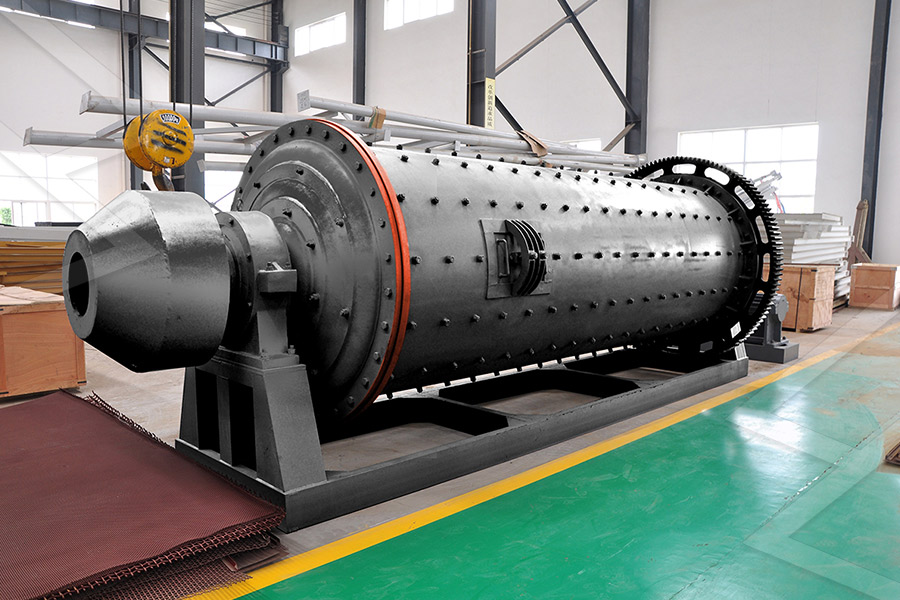

Cone crushers are a type of primary crushing machine that consists of two rotating grinding cones, which interact with each other to crush the material They have different capacities Based on the latest technology and decades of production experience, the cone crusher developed by SBM has excellent crushing efficiency and a good hydraulic control system and is widely used in secondary crushing of various mines and Cone Crusher SBM Ultrafine Powder TechnologyXMQ series cone ball mill is a laboratory grinding equipment for wet grinding of ore (150×50 cone ball mill can also be used for dry grinding) It is suitable for mineral feasibility study of Ball mill introduction Mining, LabCone ball mill is a common ball mill of mining processing This ball mill changes former structure of ball mill, and it enables the integration of body and chassisOperation Principle of Cone Ball Mill XinhaiGenerally used for reducing material to a particle size as low as 180µm (80 mesh) a cone mill produces less dust and heat than alternative forms of milling The gentle grinding action and quick discharge of correctly sized particles ensure Cone Mill Conical Milling Machine for Size Reduction2024年12月12日 Mining and Metallurgy Ball mills are extensively used to grind ores into fine powders, a critical step in extracting valuable minerals like gold, silver, and copper They help in refining raw materials to prepare them for What Is a Ball Mill? Understanding How It Works, Its

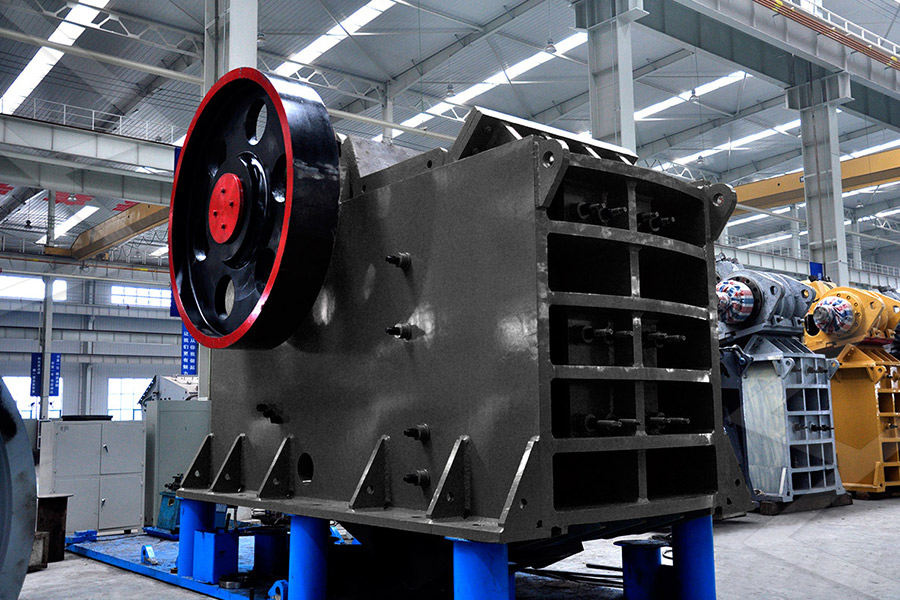

Crusher and Its Types PDF SlideShare

2019年1月10日 Jaw crushers are used for size reduction of hard and large lumps of ore Crushers employ compression to break solid materials into smaller pieces A primary crusher breaks material to 150250mm while a secondary Mill Liners and Discharge Systems for SAG/AG Mills, Rod Mills, Ball Mills, Scrubbers, and Mixing Drums Polycorp has supplied the mining industry with Mill Liner Systems since 1968 Polycorp Mill Liners have demonstrated the following benefits from Ball MillsMill Liners and Discharge Systems Engineered for PerformanceThe technical details of Castolin Eutectic‘s worldwide case studies are available in most industrial locations where Castolin Eutectic is present, with more than 9,000 fully documented applications for immediate callup in our multilingual TeroLink® systemKey Industry Program Castolin EutecticOur technical team will work with you to determine the right bit for your application Careful consideration of rock compressive strength and BHA configuration We want to be the best At DBI, we aim to be the leading provider of Roller Cone drilling tools to the energyDrilBit PVT LtdFinding suppliers of mining crushers, breakers and grinding mills Crushers, breakers and grinding mills come in several different types Mining Technology has listed some of the leading suppliers of processing equipment in the mining drills and breakers market, based on its intel, insights and decades of experience in the sector Mining Crushers, Breakers Grinding Mills for the Mining industry2022年5月19日 The gold ore crushing process often uses jaw crusher for coarse crushing, standard cone crusher for medium crushing, and short head cone crusher and roll crusher for fine crushing Most medium and small gold How to Process Gold Ore? 4 Gold Processing Steps

BALL MILL FOR ALL YOUR NEEDS FTM Machinery

Henan Fote Mining Machinery Co, Ltd is a jointstock mining machinery enterprise integrated in scientific research, production and hightech talents FOTE BALL MILL 03 FOTE BALL MILL 04 Introduction Ball Mill Ball mill is the key equipment for It is also A large number of SAG Mills have been supplied to the mining industry, of which 25% are of the innovative openend discharge design supported on slipper pad bearings FLSmidth have a range of mills that can be delivered and custom Grinding Mills FLSmidth DorrOliver Eimco PDF China Cone Mills wholesale Select 2025 high quality Cone Mills products in best price from certified Chinese manufacturers, suppliers, Discover the perfect addition to your Mining Mill with our Cone MillsSuppliers typically offer a variety of Mining Mill types Cone Mills MadeinChinaCone Mill for Size Reduction Increase productivity and improve production versatility and reliability across a wide array of dry milling and wet conditioning applications with conical milling Cone milling is one of the most common methods of milling in the pharmaceutical , food , chemical and associated industriesCone Mill Conical Milling Machine for Size Reductiontechnology, construction, working and maintenance of crushers for bulk materials is given in this article Crushing Technology There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition Most crushers employ aConstruction, Working and Maintenance of Crushers for Crushing Cone crusher is a kind of jaw crusher which have the unique feature that it can crush various kinds of materials by using the help of a conical shaped crushing chamber cone crushers are widely used in mining, construction and other industrial applications forTechnical specifications of cone crusher of 350 to 400 tph capacity

.jpg)

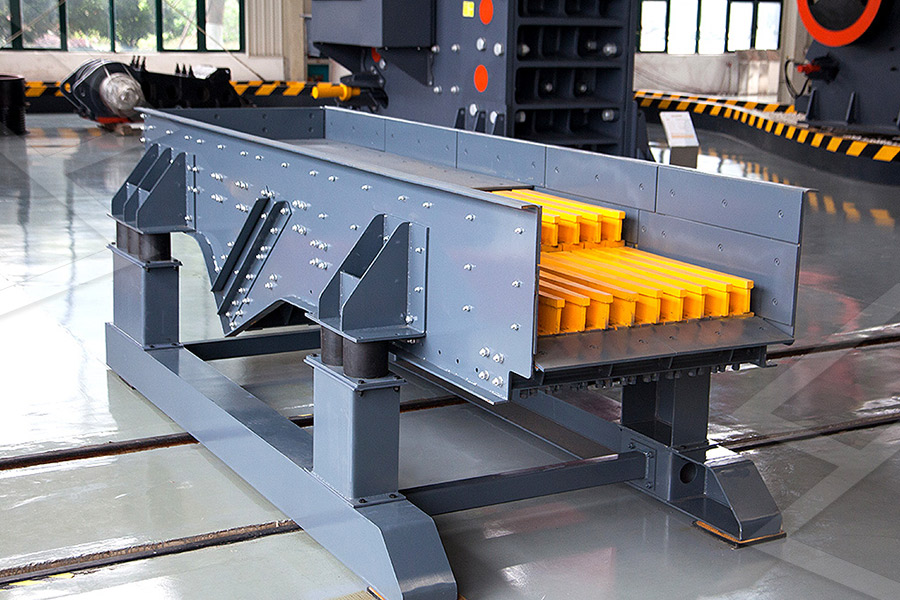

Vertical Roller Mills used for the comminution of mineral ores

The Pfeiffer pilot mill used in this study is a semiindustrial vertical roller mill of type MVR with a table diameter of 400 mm The mill can be equipped with different classifiers for specific applications The process layout of the plant (Figure 2) corresponds to that of anRice Milling 33 Multiple pass rice milling Commercial Mill The milling process in larger commercial mills combines a number of operations that produces higher quality and higher yields of white rice from paddy or rough rice The process involves: 1 PrecleaningRice Milling Manual International Rice Research InstituteHome > Mining Equipment > abb 8500 hp ball mill motor technical data a complete library of practical technical information relating to the ABB Gold ore crusher mill, gold ball mill liming is a complete gold ore crusher mill manufacturer in China, Complete Technical Data Of Ball Mills Crusher Mills, Cone 2024年5月19日 (PDC) drill bits are crucial for efficient, durable drilling They use synthetic diamond cutters bonded to tungsten carbide, shearing through rock formations This boosts drilling speed by 3050% and cuts bit change Technical Details and Mechanisms of PDC Drill Bits2018年6月1日 The sizedistribution variations that are encountered in the feed to an individual plant can be considerable Examples of a threestage crushingplant flowsheet, using two stages of cone crushers, to provide feed for single Cone Crushers: Types, Benefits, and ApplicationsA CHOICE f OR TODAY AND TOMORRO w A crusher is a major investment, so it’s essential to select one with the potential to meet your needs into the future This guide covers a few of the key points to consider before making a decision But remember that yourMASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE Sandvik Mining

List of types of mill Wikipedia

(See comminution, filtration) Arrastra, simple mill for grinding and pulverizing (typically) gold or silver ore Ball mill, a mill using balls to crush the material Bead mill a type of Mill (grinding) Burr mill or burr grinder, a mill using burrs to crush the material, usually manufactured for a single purpose such as coffee beans, dried peppercorns, coarse salt, spices, or poppy seedslaboratory disc mill is mainly used for medium hardness ore crushing thedisc pulverizer is Widely used in metallurgy, geology, mining, building materials and chemical industry departments Skip to content +86 export6@jxscmining Home laboratory disc mill for sample preparation walkertechnology, construction, working and maintenance of crushers for bulk materials is given in this article Crushing Technology There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition Most crushers employ aConstruction, Working and Maintenance of Crushers for Crushing From design and manufacture to installation, commissioning, and a comprehensive aftermarket service, Harcliff mills are designed with costeffectiveness in mind Fasttracked deliveries are undertaken when required Harcliff sizes and designs new mills to suite and Grinding Mills HarcliffCone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always) Cone Crusher Components (Crusher Parts) The main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, ,Cone Crushers (Parts of a Cone Crusher) Explained saVRee2016年3月11日 To reduce runofmine to mill feed requires reduction in a series of stages The physical size and power requirements of a crusher capable of reducing hard rock vary depending on the application Extended experience in most crushing plants show that a minus 19MM (¾”) rod mill feed can be and is being produced in three stages of crushingCrushing Plant Flowsheet DesignLayout 911Metallurgist

.jpg)

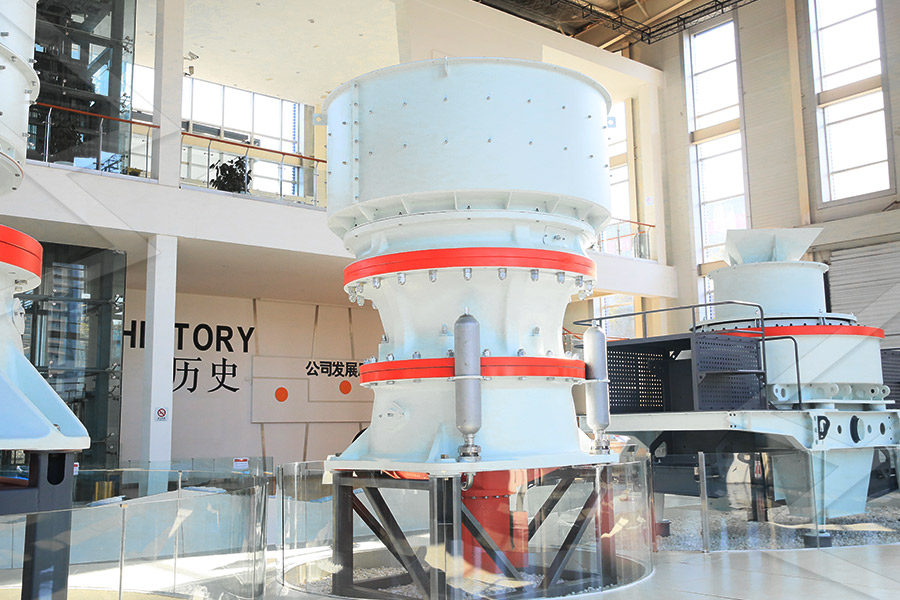

Cone Mills – Mineral Innovative Technologies

Cone mills are designed to crush and pulverize hard and brittle bulk materials of various strengths In the cone mill, pulverization occurs by means of abrasion – simultaneous compressive and shear strain of material particles between the outer and inner shells2024年12月12日 Mining and Metallurgy Ball mills are extensively used to grind ores into fine powders, a critical step in extracting valuable minerals like gold, silver, and copper They help in refining raw materials to prepare them for What Is a Ball Mill? Understanding How It Works, Its 2019年1月10日 Jaw crushers are used for size reduction of hard and large lumps of ore Crushers employ compression to break solid materials into smaller pieces A primary crusher breaks material to 150250mm while a secondary Crusher and Its Types PDF SlideShareMill Liners and Discharge Systems for SAG/AG Mills, Rod Mills, Ball Mills, Scrubbers, and Mixing Drums Polycorp has supplied the mining industry with Mill Liner Systems since 1968 Polycorp Mill Liners have demonstrated the following benefits from Ball MillsMill Liners and Discharge Systems Engineered for PerformanceThe technical details of Castolin Eutectic‘s worldwide case studies are available in most industrial locations where Castolin Eutectic is present, with more than 9,000 fully documented applications for immediate callup in our multilingual TeroLink® systemKey Industry Program Castolin EutecticOur technical team will work with you to determine the right bit for your application Careful consideration of rock compressive strength and BHA configuration We want to be the best At DBI, we aim to be the leading provider of Roller Cone drilling tools to the energyDrilBit PVT Ltd

.jpg)

Mining Crushers, Breakers Grinding Mills for the Mining industry

Finding suppliers of mining crushers, breakers and grinding mills Crushers, breakers and grinding mills come in several different types Mining Technology has listed some of the leading suppliers of processing equipment in the mining drills and breakers market, based on its intel, insights and decades of experience in the sector