Sand Castings And Moldings

Guide to Sand Casting: Process, Materials, and

Sand casting uses sand as the molding material to create a cavity for pouring molten metal, which then solidifies into the desired shape Additionally, it is known as sandmolded casting Almost all casting metals can be applied in sand 2024年2月22日 Sand casting is a metal casting process that uses sand as the primary molding material It is one of the oldest and most widely used casting methods due to its versatility, flexibility, and costeffectiveness The working The 6Step Process of Sand Casting: A StepbyStep 2019年10月30日 Also known as sand molding casting, sand casting is a castingbased manufacturing process that involves the use of a sand mold It’s used to create metal products and components in a variety of sizes and shapes To The 6Step Process of Sand Casting Molding2024年1月1日 Sandcasting is a casting process created in ancient China It is also known as sand molding cast The process is as follows: First, the lower half of the model is placed on the SandCasting SpringerLink2024年6月28日 Casting forming is divided into two major categories: sand casting and special casting, based on mold materials, molding methods, and pouring conditions Sand casting is a traditional casting method with flexible Breakdown Of Sand And Special Casting Techniques2025年2月24日 Sand casting is a timetested process that uses sand molds to create metal parts, valued for its versatility and simplicity The process begins with creating a pattern, which Sand Casting: Process, Techniques, and Benefits MFG Shop

Casting Processes: Sand Casting

Sand casting is a process that involves creating a mold from a sand mixture and pouring molten metal into the mold to form a desired shape This article delves into the intricacies of sand 2025年1月16日 This type of sand molding provides better dimensional accuracy and a superior surface finish but increases production costs Choosing between resinbonded and green sand castings depends on the specific requirements What is Sand Casting? (Learn its Essential Facts) TFG How Does Sand Casting Work? With this fundamental understanding in place, we can explore how sand casting is executed in practice Here’s a stepbystep breakdown of how sand casting works: Sand Preparation: This involves Guide to Sand Casting: Process, Materials, and Sand casting is one of the oldest and most widelyused methods of metal casting, dating back to around, and even before, 10,000 BC The process employs sand for the main mold material, as this material can be shaped and compacted to Sand Casting Process: A StepbyStep Guide Bunty LLCImpro is a globally recognized manufacturer of complex and highvalueadded sand castings for diverse end markets We have two resinsand production lines and one manual molding line IMF Automatic Molding Line: for small parts 15 molds/hour/li> Sand Casting Equipment Resin Sand Green Sand Casting 2025年1月4日 Shell molding involves precoated sand molds, yielding highprecision castings Each method has distinct advantages and applications, allowing for a range of metal parts with varying precision and surface quality, as discussed earlier in the guideThe Comprehensive Guide to Sand Casting MFG Shop

.jpg)

Sculpture Casting, Molding, Materials Britannica

Sculpture Casting, Molding, Materials: These are used for producing a single cast from a soft, plastic original, usually clay They are especially useful for producing master casts for subsequent reproduction in metal The basic procedure is as follows First, the mold is built up in liquid plaster over the original clay model; for casting reliefs, a onepiece mold may be sufficient, but for 2017年9月19日 Patriot Foundry is a nationally trusted nonferrous foundry with decades of experience in sand castingIf you need help deciding which type of sand might be best for your sa19nd casting project, leave the hard work to us! The 3 Types of Sand Used for Sand Casting Patriot RGanesh Narayanan, IITG Limitations • Dimensional accuracy and surface finish of the castings made by sand casting processes are a limitation to this technique • Many new casting processes have been developed which can take into consideration the aspectsMetal casting processes IIT GuwahatiTypes of Molding Sand Molding sands can also be classified into various types according to their use are backing sand, core sand, dry sand, facing sand, green sand, loam sand, parting sand, and system sand #1Backing sand or floor sand Backing sand or floor What is Molding Sand? Types And PropertiesNo bake sand castings provide a versatile option for metal casting This process can produce parts and components in a wide range of shapes and sizes The rigid molds produced for an air set sand casting provide good dimensional tolerances and control No bake No Bake, Air Set Casting Dry Sand Precision Molding FoundryMolding Sand: A mixture of sand, clay, and water (green sand) or chemically bonded sand Cope and Drag : The mold is split into two halves to facilitate pattern removal and metal pouring Compaction Methods : Sand is compacted around the pattern using ramming or vibration techniques to ensure a dense, stable moldSand Casting: A Comprehensive Guide

Sand Castings Stainless Steel Sand Casting MetalTek

2020年11月23日 MetalTek’s Carondelet Division produces sand castings in a modern, highlyautomated facility and is a preferred supplier for small to medium production runs Carondelet features an inhouse pattern shop and IMF, patternless, automated isocure, 2020年5月6日 The Loam sand with 50% of clay is called loam sand They are also suitable for large castings It is a mixture of sand and clay and water is present in such a quantity that it forms a thin plastic paste In these types of sand, moulding patterns are not used The Moulding Sand: Properties and Types of Moulding Sand The For over 45 years Norse has built up a reputation for supplying a diverse range of customers throughout the UK and Europe with quality aluminium sand castings Specialising in the manufacture of highly complex, technical, thin walled and exceptionally well finished aluminium parts at competitive pricesNorse Precision Sand Castings Aluminium Rigid Polyurethane Alpha Set and Shell Molding Sand casting foundry for steel alloy castings for valves, pumps, wearresistant liners, furnace grates and incinerator stokers [ protected] +14164235590 Generic selectorsSteel Casting Foundry Alpha Set Shell Molding Sand CastingDry sand molding is ideal for creating castings with radical geometries such as deep pockets or thing ribs Dry sand castings often require high strength and tight sealing characteristics Tooling cost is relatively low, and we utilize a series of innovative dry sand Molding Processes Capabilities Custom Precision Molds2025年2月11日 Using a baking tray to contain sand during molding is crucial Although some spillage is inevitable, the tray significantly shot blasting, and machining By following these steps, highquality sand castings are produced efficiently, making sand casting a reliable Understanding Sand Casting MFG Shop

Comprehensive Guide to Sand Casting Process MFG Shop

2025年1月19日 Sand casting, also known as sand molding, is a widely used process for creating metal parts by pouring molten metal into a sand mold This method is highly favored in the manufacturing industry due to its versatility and costeffectiveness2015年3月20日 GredeSt Cloud, a green sand molding operation producing iron castings, operates two molding lines, each with its own sand system For each line, daily tests are used to quantify variation within the sand system and make corrections as needed to keep within the optimal performance rangeGreen Sand Control Best Practices Modern CastingAll About Sand Casting XometryAll About Sand Casting XometryFormerly this process was widely used in Europe for hardening of moulds and cores made of green sand, but now adays, it has been adopted in several countries because of rapid hardening of sand It consists of thorough mixing of silica sand (clean, dry and free from clay) with 35 to 5% by weight of sodium silicate liquid base binder in a muller Sometimes coaldust, pitch, Carbon Dioxide Process for Mould Hardening Casting MetallurgyImpro Industries is globally recognized as a leading provider of sand castings We have over 20 years of experience in creating highend, geometrically complex sand castings from highgrade materials We offer both machine and manual molding operations for resin Sand Casting Companies Sand Molded Metal PartsAnnual Capacity of Sand Castings: 5,000 tons 6,000 tons Casting Tolerances: On Request or According to ISO 8062 Capabilities of Sand Casting by Automatic Molding Machines: Max Size of Casting Molds: 1,000 mm × 800 mm × 500 mm Weight Range ofSand Casting Foundry Cast Iron Sand Casting Company Grey

What Is Sand Casting? General Kinematics

2023年10月24日 Sand castings on a GK shakeout conveyor After the molten metal is poured, it cools and solidifies within the mold Cooling time varies depending on the size and complexity of the casting– larger objects will take longer to cool compared to small objects Proper Sand casting is a metal forming process in which a mold is first formed from a threedimensional pattern of sand, and molten metal is poured into the mold cavity for solidification The sand shell is subsequently removed after the metal components cooled and formed Sand casting is a costeffective and efficient technology, which is generally flexible with regards to size and change of Sand Casting Process Introduction Impro PrecisionSome common names can list down such as green sand molding, lost foam casting, investment casting, permanent mold casting, etc Continue series of the blog of molding technology , Vietnam Cast Iron introduces a popular and widely applied method in What is furan resin sand casting Vietnam Cast Iron2025年1月16日 This type of sand molding provides better dimensional accuracy and a superior surface finish but increases production costs Choosing between resinbonded and green sand castings depends on the specific requirements What is Sand Casting? (Learn its Essential Facts) TFG How Does Sand Casting Work? With this fundamental understanding in place, we can explore how sand casting is executed in practice Here’s a stepbystep breakdown of how sand casting works: Sand Preparation: This involves Guide to Sand Casting: Process, Materials, and Sand casting is one of the oldest and most widelyused methods of metal casting, dating back to around, and even before, 10,000 BC The process employs sand for the main mold material, as this material can be shaped and compacted to Sand Casting Process: A StepbyStep Guide Bunty LLC

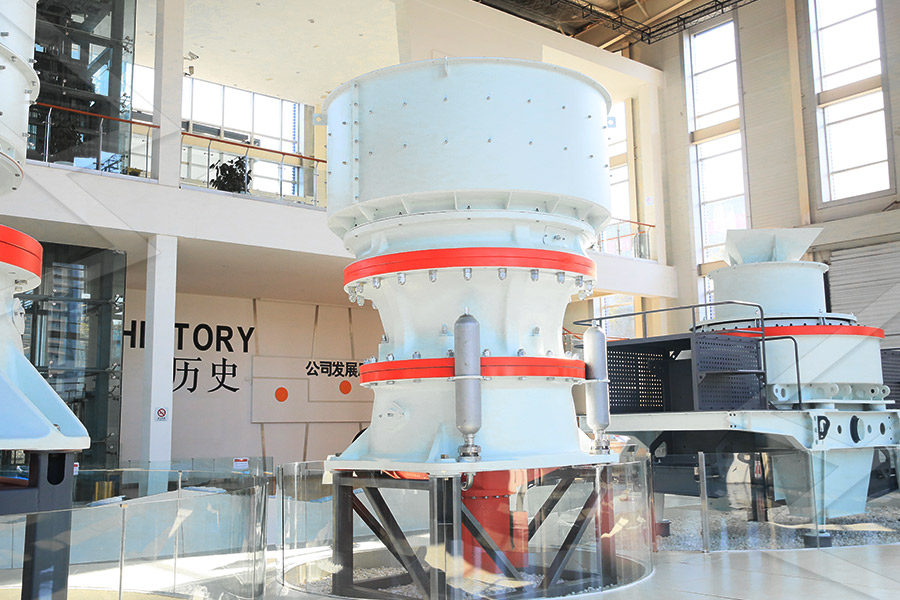

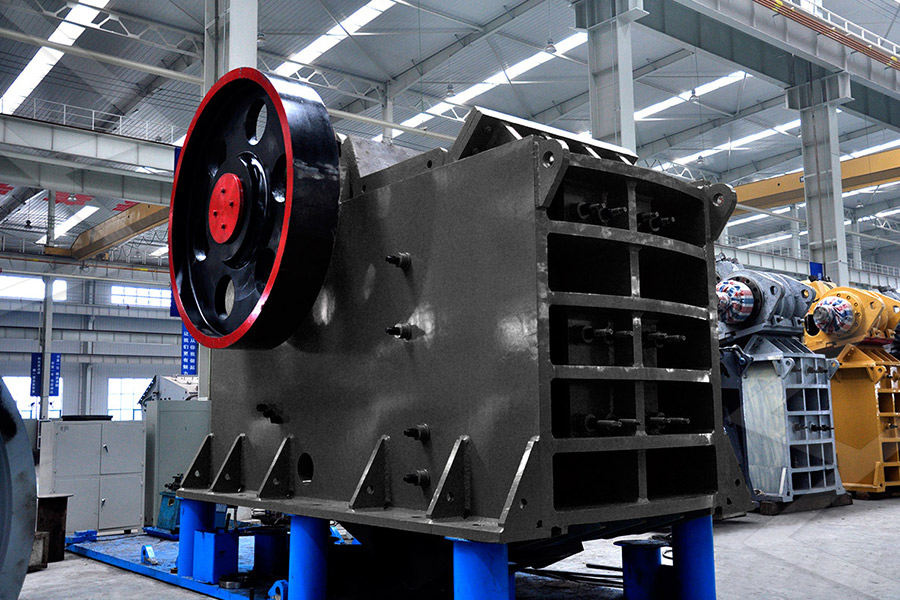

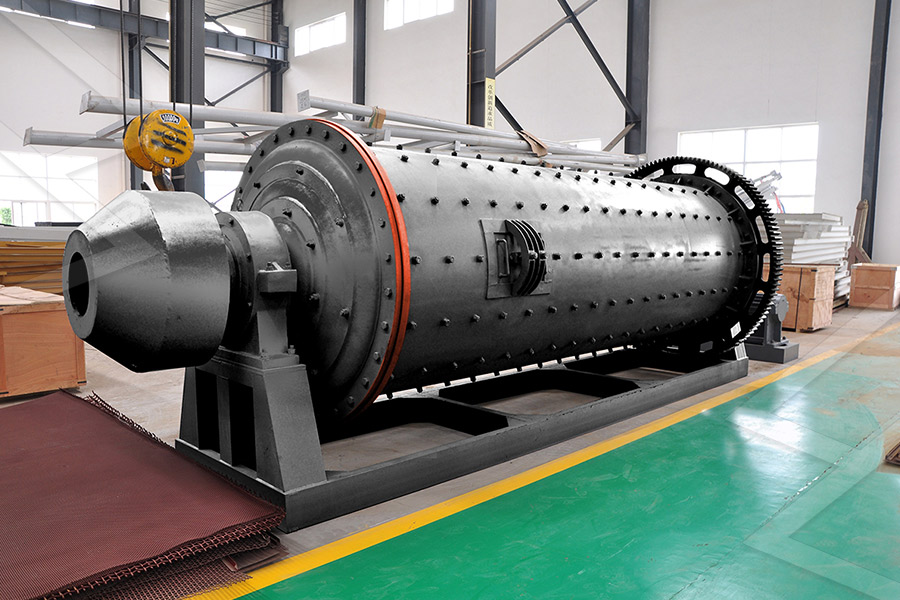

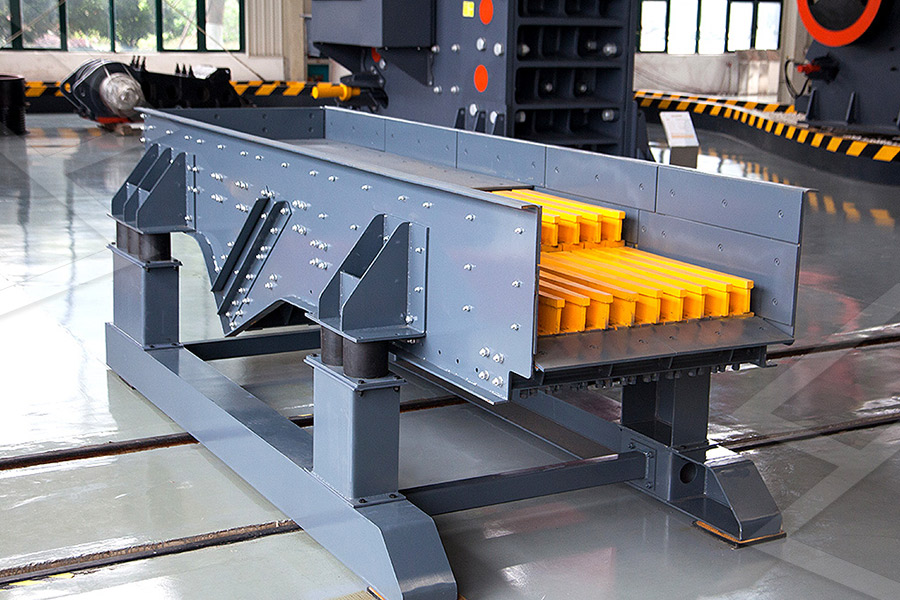

Sand Casting Equipment Resin Sand Green Sand Casting

Impro is a globally recognized manufacturer of complex and highvalueadded sand castings for diverse end markets We have two resinsand production lines and one manual molding line IMF Automatic Molding Line: for small parts 15 molds/hour/li> 2025年1月4日 Shell molding involves precoated sand molds, yielding highprecision castings Each method has distinct advantages and applications, allowing for a range of metal parts with varying precision and surface quality, as discussed earlier in the guideThe Comprehensive Guide to Sand Casting MFG ShopSculpture Casting, Molding, Materials: These are used for producing a single cast from a soft, plastic original, usually clay They are especially useful for producing master casts for subsequent reproduction in metal The basic procedure is as follows First, the mold is built up in liquid plaster over the original clay model; for casting reliefs, a onepiece mold may be sufficient, but for Sculpture Casting, Molding, Materials Britannica