Songling Main Product Double Roll Rock Crusher

Double Roll Crusher CPC GmbH Crushing Processing

Crushing of the feed material by teeth as well by pressure, hydraulically induced Successive comminution of larger lumpsSMOOTH ROLL CRUSHER SR11 Features Fast rotating rollers independently Smooth Roll CrusherDouble roll crushers are used for both, primary and secondary crushing They guarantee a strictly defined final grain size with a minimum of fine grains Raw materials, secondary materials and 2PG SERIES DOUBLE ROLLER CRUSHERDouble roll crushers help producers achieve the strict coal specifications they need to meet Used as a primary or secondary unit, double roll crushers can be used in nearly any application with Double Roll Crushers Astec DefaultOur unique double roll crushing principle and segment design has resulted in improved plant efficiencies and more profit for our clients by reducing the amount of fines generated through Double roll MincotechThis document provides information about a toothed double roll crusher, including its range of applications, method of operation, constructional features, and technical specifications It can be used for primary and secondary crushing of Double Roll Crusher PDF Mechanical Engineering

.jpg)

Double roll crusher thyssenkrupp Polysius

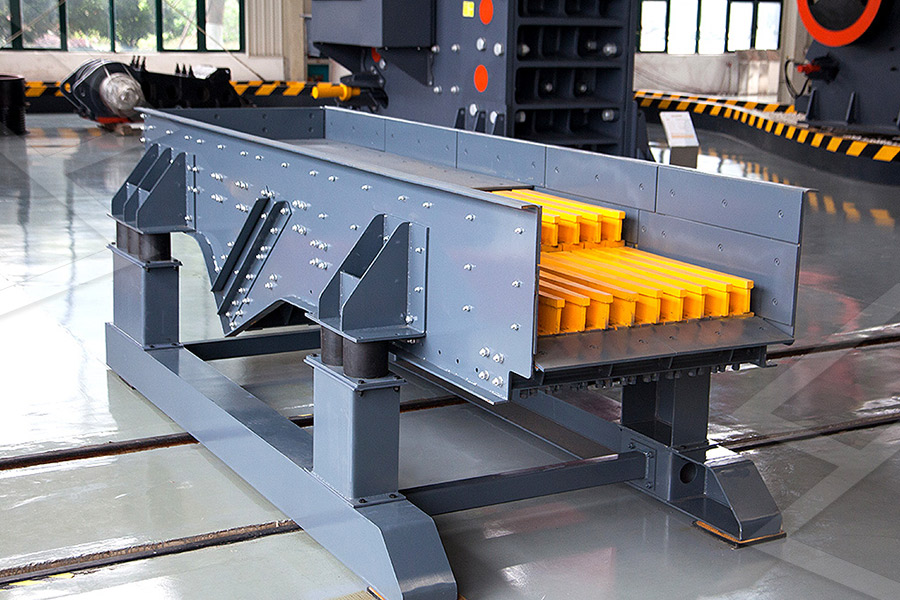

DoubleRollCrushers are used for the crushing or mediumhard rock as well as for sticky and soft materials, ie clay, marl, limestone and similar raw materials Sticky and soft materials are reliably crushed in 2 or 3 stages down to the The DRC series roller crusher is widely used in tertiary crushing with the material feeding size less than 30mm and the product size 1 10mm of artificial sand making (cobblestone and construction waste), mineral separation (iron ore Double Roll Crushers Moore Watson Ltd2025年3月20日 The LCS Series Double Roll Crusher is a newgeneration crushing device designed for coarse, medium, and fine crushing It integrates years of RD and production Liron® Double Roll CrusherLironTechDesigned to bite objects between the two rolls and crush the objects using a builtin hybrid mechanism that crushes material by compression action and forcedly discharges the crushed product Can crush objects of comparatively high Double Roll Crusher Product InformationDouble roll crusher Roll Crusher The DRC series roller crusher is widely used in tertiary crushing with the material feeding size less than 30mm and the product size 1 10mm of artificial sand making (cobblestone and construction waste), Double Roll Crushers Moore Watson Ltd2023年2月23日 Mineral Processing and Mining: Double roll crushers are used extensively in the mineral processing industry to crush mediumhard to hard materials such as rock or ore into smaller sizes They are commonly used in Understanding the Double Roll Crusher and Its

New insights into double roll crushing ScienceDirect

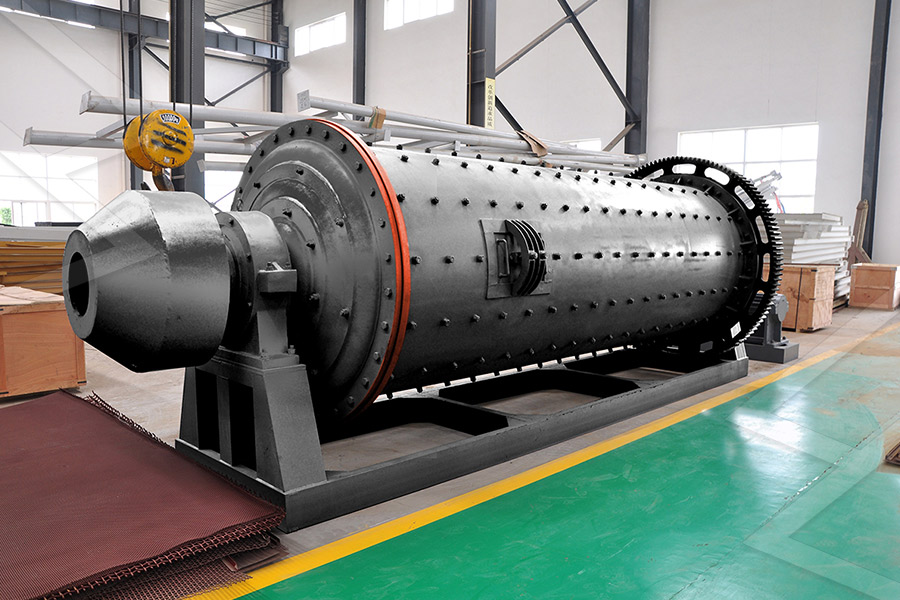

2023年11月1日 In the literature, the specifications for the degree of filling φ F usually refer to the bulk density ϱ Blk of the material and not to the raw density ϱ Raw, as assumed in equation (2)The bulk density ϱ Blk depends on the particle size and particle shape distributions of a rock fill and usually corresponds to about 50–––60% of the raw density ϱ Raw (Schmidt, 2011)The action of a roll crusher, compared to the other crushers, is amenable to a level of analysis Consider a spherical particle of radius r, being crushed by a pair of rolls of radius R, the gap between the rolls being 2a (Figure 615)If µ is the coefficient of friction between the rolls and the particle, θ is the angle formed by the tangents to the roll surfaces at their points of contact Roll Crusher an overview ScienceDirect Topics2017年4月1日 Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are preferably used to comminute mediumhard rock or sticky materials An unusual tough particle or unbreakable Dynamics in double roll crushers ScienceDirectBinder+Co Double roll crusher An optimum grain size of 10 to 50 mm is crucial for sensorbased sorting of cullet since a higher content of fines (010 mm) would have an unfavourable effect on sorting performance In the form of the double roll crusher, Binder+Co has created the ideal prerequisite for the subsequent sorting of waste glass Double Roll Crusher Binder+CoSavona Equipment is a roll crusher supplier worldwide We can supply new and used beltdriven roll crushers Roll Crushers are built to handle primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite and New Used Roll Crushers for Sale Rock Crushing Equipment Marcy® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore and can bridge the gap between laboratory and production outputs Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials from 05in (13mm) feed size to minus No 10 (2mm)Aggregate Crushers, for Rock, Ore Minerals Gilson Co

.jpg)

Roll Crusher, Large Double Roll Crusher, Double Stage Crusher, Double

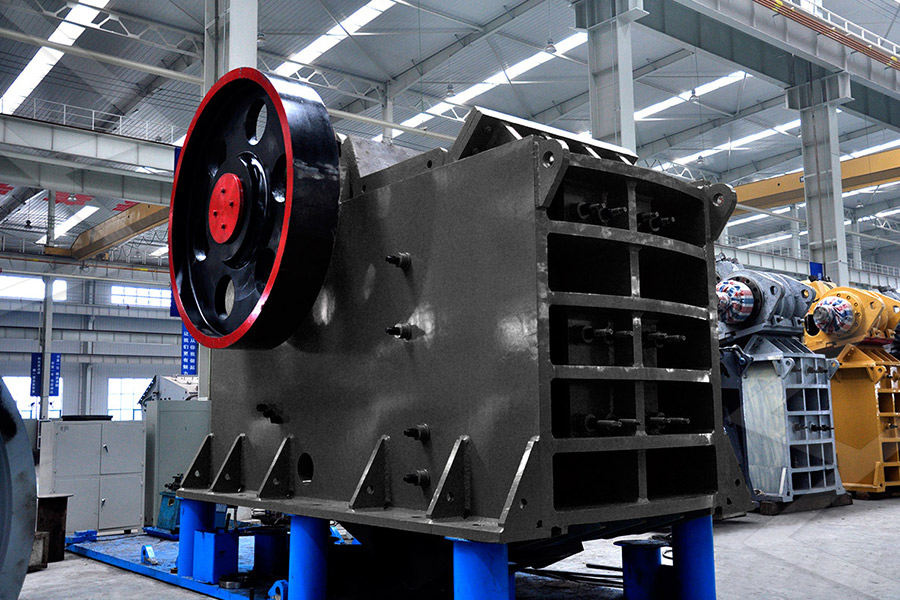

Double Roll Crusher: Suitable Materials and Key Considerations Double roll crushers utilize two counterrot Δ search About Company Profile Contact us products Crusher series Pulverizer series Screening series Sand washing series Sand production line 2015年10月18日 A crusher is a machine that reduces large rocks into smaller pieces by using impact, attrition, shear, or compression There are four main types of crushers: jaw crushers, gyratory crushers, cone crushers, and roll Roll crusherppt SlideShareDoubleRollCrushers are used for the crushing or mediumhard rock as well as for sticky and soft materials, ie clay, marl, limestone and similar raw materials Sticky and soft materials are reliably crushed in 2 or 3 stages down to the Double roll crusher thyssenkrupp PolysiusDouble Roll Crushers are one of the most widely used crushers in the mining industry and have numerous advantages, such as high capacity, low headroom, low horsepower, the ability to handle wet, sticky feeds and the ability to Double Roll Crushers McLanahanThe Marcy® Double Roll Crusher has Cast NiHard Roll Facing grinding elements perfect for rock, ore and minerals for final a particle size of 2mm Roll Crusher Double Roller Crusher DOVE DOVE Roll Crusher also referred to as Double Roller Crusher, or Twin Roll Crusher is highly efficient crushing machine for primary, secondary and tertiary crushing applicationsSongling Tengda Double Roller CrusherThe type of rock crusher required depends on moisture content, the hardness of the material, and your desired product size Crushing may take place in one process with a single crusher However, secondary and tertiary crushing can be used to Rock Crushers Pulverizers Williams Crusher

Tugas pengolahan bahan galian double roll crusher PDF

2013年3月20日 Tugas pengolahan bahan galian double roll crusher Download as a PDF or view online for free Dokumen ini membahas tentang penyangga aktif pada tambang bawah tanah, termasuk jenisjenis penyangga aktif seperti baut batuan, hydraulic props, dan powered roof DOUBLE ROLL CRUSHER DR13 Features Solution for mediumhard rock as well as sticky and soft materials (coal, limestone, clay, salt, etc) Weldon hardfaced crushing teeth with various configurations for most difficult applications Integrated flywheel equalizing torque peaks, thus reducing required motor power Permanent parallel position of crushing rolls due to hydraulic Double Roll Crusher CPC GmbH Crushing ProcessingUserfriendly, highfunctional Crusher Supports a wide variety of crushed particle sizes Designed to bite objects between the two rolls and crush the objects using a builtin hybrid mechanism that crushes material by compression action and forcedly discharges the crushed productDouble Roll Crusher [ KURIMOTO, LTD Indonesia ]Figure 1: Double roll crusher geometry 215 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5] For rolls that have equal radii andDesign, Fabrication and Testing of a Double Roll CrusherDouble roller crusher is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials What’s the double roller crusher】 The Doule Roller Crusher, also known as roll crusher, or toothed roll crusher, is suitable for fine crushing medium hardness rock with Double Roller Crusher JXSC Machine自1989年以来,吴江市松陵电器设备有限公司一直从事于设计,制造,组装,定制工业干燥设备的业务。我们为不同行业领域合作的35年经验使得我们非常了解干燥行业的需求。目前松陵已经开发了一系列鼓风干燥设备和真空干燥设备,适用 吴江市松陵电器设备有限公司松陵电器江陵电器设备

Onestop Turnkey ROLL CRUSHER FTM Machinery

FOTE ROLL CRUSHER 06 There is a movable device on the movable roller to protect the machine from damage In case any noncrushed materials or metals drop into the cavity and can’t go through the clearance between the rollers, there is equipped with a2022年2月10日 The doubleroll crusher is mainly suitable for coarse and intermediate crushing of brittle bulk materials in mining, metallurgy, chemical industry, coal mine and other industries Especially in the coal industry, when What’s a DoubleRoller Crusher? Eastman Rock Roller crusher is a very old crushing equipment that appeared in 1806, and its structure is simple It can crushers iron ore, Quartz Stone, rock gold, rock tantalum niobium ore, rock tin ore, rock tungsten ore, manganese ore, ilmenite ore, Kalbite, limestone, river Roller Crusher Single/Double Roll Crushers JSXC MineTramp can also refer to inclusions in the material feed to a machine (ie crusher) that the machine is not designed to handle For example, a large particle of hard rock would be considered tramp for a Double Roll Crusher since Double Roll Crushers are notSampling Sizers/Roll Crushers McLanahanRoll Crusher for Sale The standard spring roll crusher have two horizontally mounted cylinders The set is determined by spacing pieces (shims) which cause the springloaded roll to be held back on its sliding mounting from the solidly mounted roll Modern rolls have both cylinders positively driven by separate motors, so that they rotate inward and downward Rolls crush by Roll Crushers 911Metallurgist2024年9月6日 The double roller sandmaking machine, also known as a roller crusher, is a mining machinery that integrates various technologies It performs fine crushing and sandmaking operations This machine has a reasonable structure, small size, and high efficiency, which make it Double Roller Crusher Machine For Sand Making Eastman Rock Crusher

Machines EDGE RS1500 Roll Sizer Crusher Works

Edge RS1500 Roll Sizer (Double Roll Crusher) The EDGE – ROLL SIZER offers a new concept in mineral sizing solution The EDGE RS1500 roll sizer has been designed for the secondary and tertiary crushing of mediumhard, sticky and soft materials such as coal, lignite, clay, limestone and other bituminous and subbituminous materialsOur crushers are widely accepted across various industrial sectors like metallurgy, mining, building material, energy, etc Our product range includes – single and double toothed roll crushers, smooth double roll crushers, and sinter crushersCrushers supplier and exporter, Supplying CrushersDOVE Roll Crushers are highly versatile, configured with easy adjustments in Rollers Speed The Rollers Gap strings of the Roller Crusher is designed to be easily adjusted with the gap setting of (1 – 20 mm), in order to meet the requirements for various particles crushing sizes, and any application requirements Roll Crusher Double Roller Crusher DOVE DOVE Equipment Double roll crusher Roll Crusher The DRC series roller crusher is widely used in tertiary crushing with the material feeding size less than 30mm and the product size 1 10mm of artificial sand making (cobblestone and construction waste), Double Roll Crushers Moore Watson Ltd2023年2月23日 Mineral Processing and Mining: Double roll crushers are used extensively in the mineral processing industry to crush mediumhard to hard materials such as rock or ore into smaller sizes They are commonly used in Understanding the Double Roll Crusher and Its 2023年11月1日 In the literature, the specifications for the degree of filling φ F usually refer to the bulk density ϱ Blk of the material and not to the raw density ϱ Raw, as assumed in equation (2)The bulk density ϱ Blk depends on the particle size and particle shape distributions of a rock fill and usually corresponds to about 50–––60% of the raw density ϱ Raw (Schmidt, 2011)New insights into double roll crushing ScienceDirect

.jpg)

Roll Crusher an overview ScienceDirect Topics

The action of a roll crusher, compared to the other crushers, is amenable to a level of analysis Consider a spherical particle of radius r, being crushed by a pair of rolls of radius R, the gap between the rolls being 2a (Figure 615)If µ is the coefficient of friction between the rolls and the particle, θ is the angle formed by the tangents to the roll surfaces at their points of contact 2017年4月1日 Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are preferably used to comminute mediumhard rock or sticky materials An unusual tough particle or unbreakable Dynamics in double roll crushers ScienceDirectBinder+Co Double roll crusher An optimum grain size of 10 to 50 mm is crucial for sensorbased sorting of cullet since a higher content of fines (010 mm) would have an unfavourable effect on sorting performance In the form of the double roll crusher, Binder+Co has created the ideal prerequisite for the subsequent sorting of waste glass Double Roll Crusher Binder+CoSavona Equipment is a roll crusher supplier worldwide We can supply new and used beltdriven roll crushers Roll Crushers are built to handle primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite and New Used Roll Crushers for Sale Rock Crushing Equipment Marcy® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore and can bridge the gap between laboratory and production outputs Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials from 05in (13mm) feed size to minus No 10 (2mm)Aggregate Crushers, for Rock, Ore Minerals Gilson CoDouble Roll Crusher: Suitable Materials and Key Considerations Double roll crushers utilize two counterrot Δ search About Company Profile Contact us products Crusher series Pulverizer series Screening series Sand washing series Sand production line Roll Crusher, Large Double Roll Crusher, Double Stage Crusher, Double